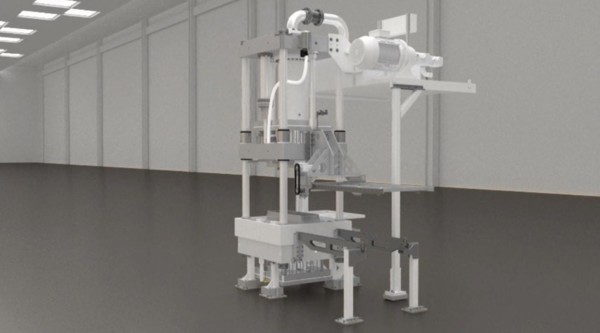

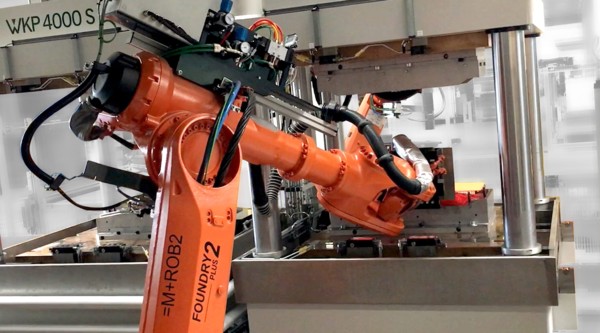

In addition, for sharply contoured forming operations which do not permit any grooves in the tool, a flux gap can be formed. This is done with servo-hydraulically driven contour pins which hold the component in suspension with the tool slightly open, thus allowing the hardening medium to flow effectively into the component.