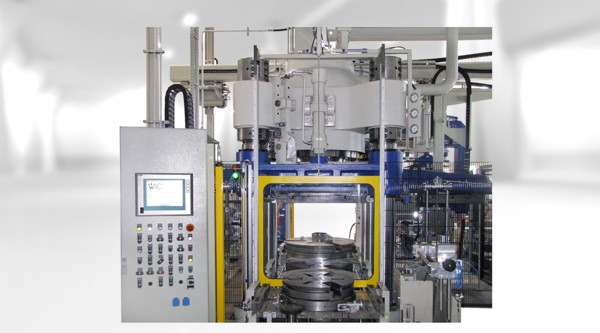

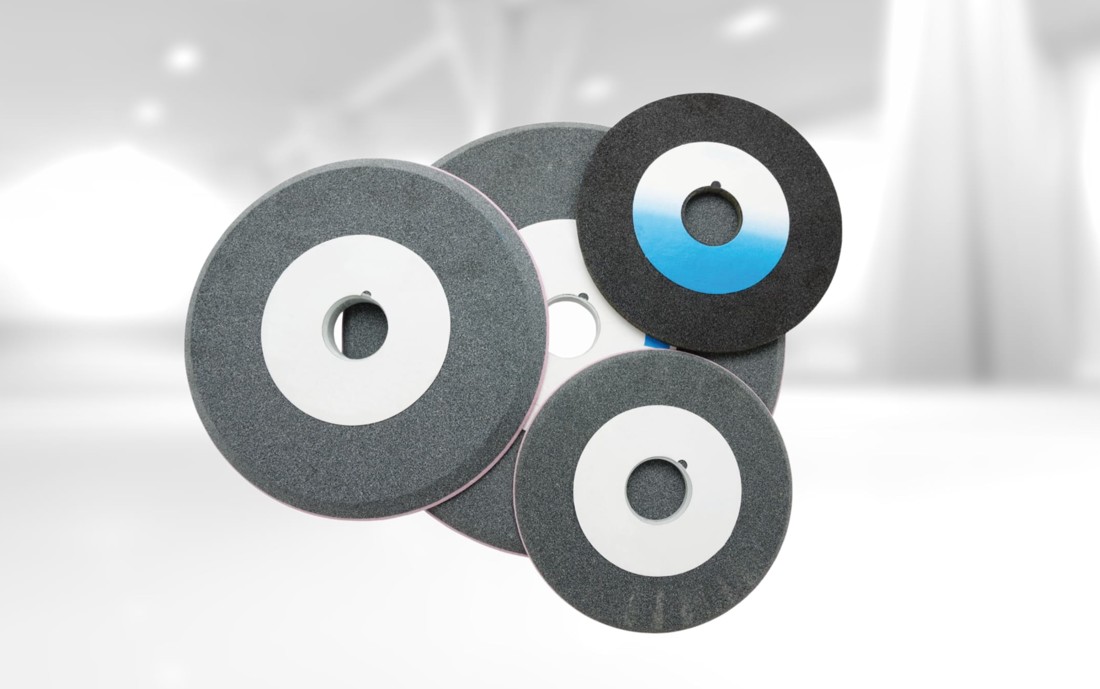

Thanks to its modular design, the WKP S series is especially suitable for manufacturing customized grinding wheels.

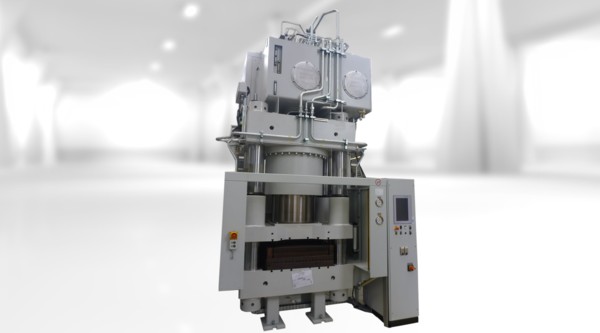

Our hot and cold presses allow users to produce various kinds of grinding wheels, such as diamond, CBN, ceramic or resin-bond grinding wheels.