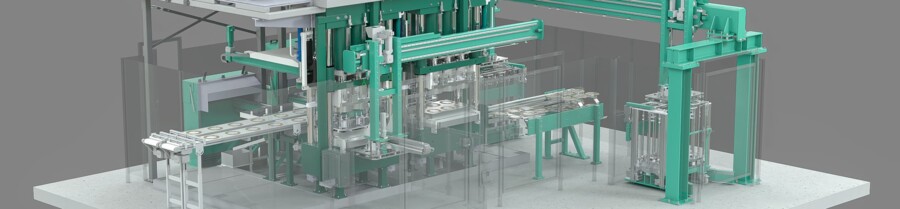

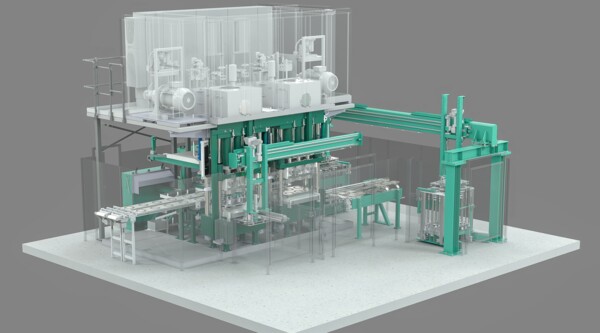

The Wickert modular system provides also solutions for customized press systems for the manufacturing of brake and clutch linings.

In addition a flexible integration of existing production processes is possible. The production process of brake linings can be hot or cold in a standard as well as specialized process. The clutch linings for wet and dry clutch systems are manufactured either in a press design with already prepared green parts or powder like in green material. In additional Wickert releases fully automated systems for hot bonding of wet clutches.