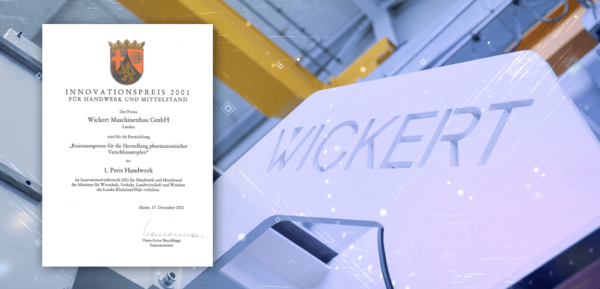

For more than 3 generations in the family - For 120 years in Landau, Germany - and a reliable partner for the future.

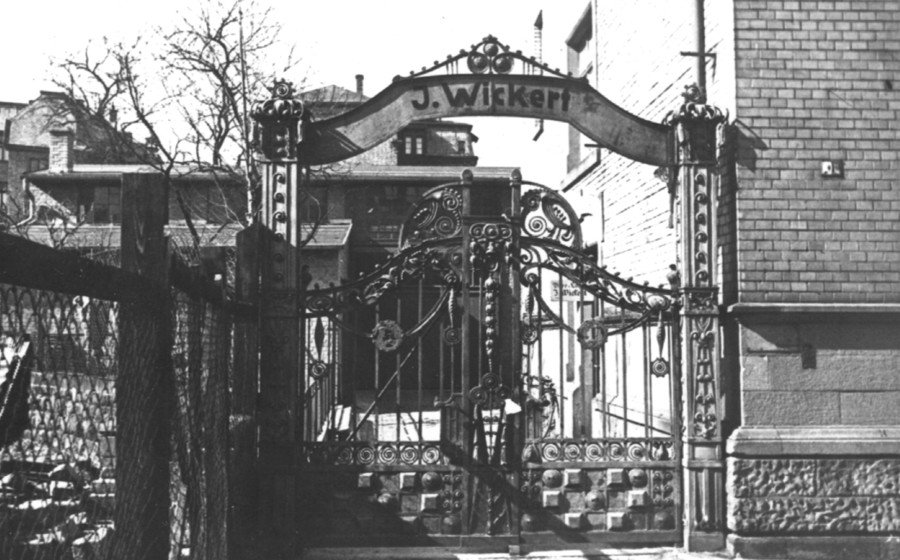

Jakob Wickert, a trained master locksmith, founded the J. WICKERT machine factory in Landau on May 4th, 1901. Together with 8 journeymen and 5 apprentices he started to build presses. What could be more logical than to develop and produce presses for wine and fruit growing in what is still the largest wine-growing community in Germany today?

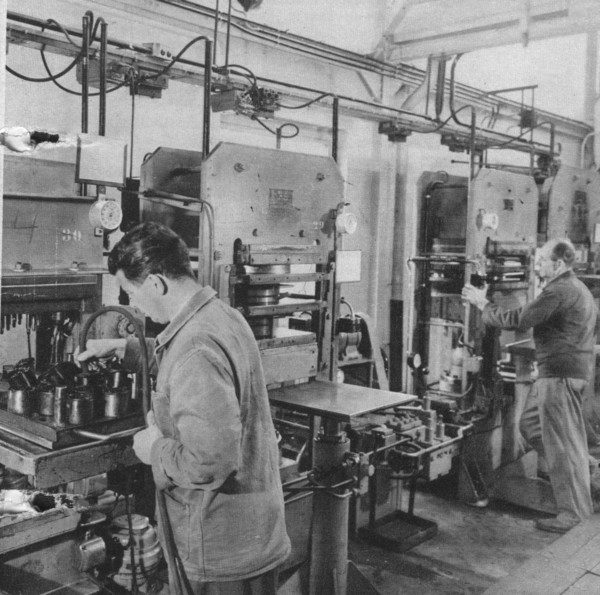

The WICKERT presses have always met the highest standards, for example: the hydraulic top-pressure wine press presented in June 1938. The spindle presses available in various sizes were also equipped with modern hydraulic press units. Early on Jakob Wickert began thinking about transferring his experience in press construction to other fields of application. In 1939, dewatering presses for cotton were developed. The product range was expanded in 1948 to the extent that is still valid today.