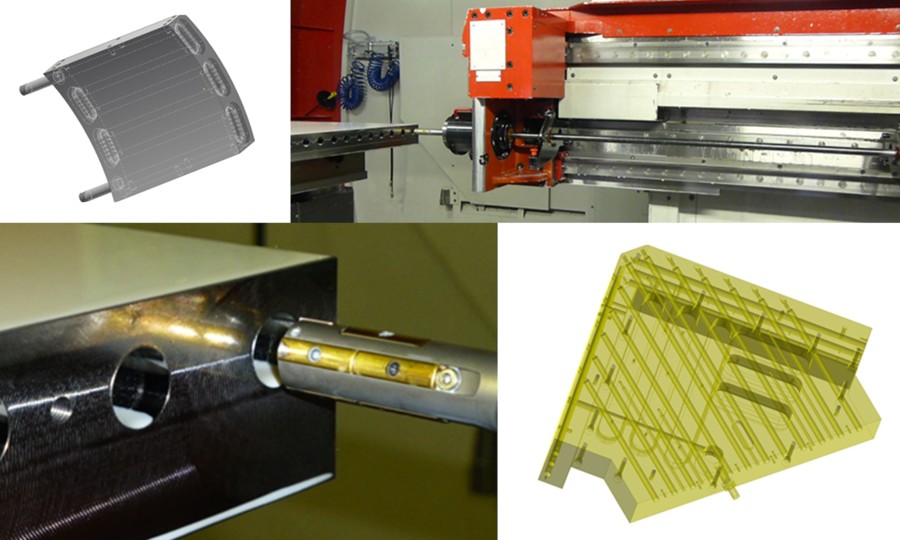

Quenching of a component heated to hardening temperature (usually circuit boards) in a cooled tool, i.e. indirect cooling.

The components do not come into direct contact with the coolant.

The component can either be formed and hardened or only held and hardened.

Advantage: The dry process means that the hardened parts do not have to be washed.

The hardening tool contains near-contour deep-hole bores which – designed for the cycle time, the required forming force or the forming contour – have specially optimized cross-sections on the printing surfaces. This guarantees that optimum heat dissipation is possible.

The rapid removal of heat and the quenching process begins as soon as the press forces the molded part to the die surface after the pressure-dependent changeover to the press force.

The cooling time can be individually adjusted to the molded part depending on the surface, amount of material, thermal conductivity and hardness to be achieved (martensitic structure) in the component recipe.