Forming and hardening in one assembly line

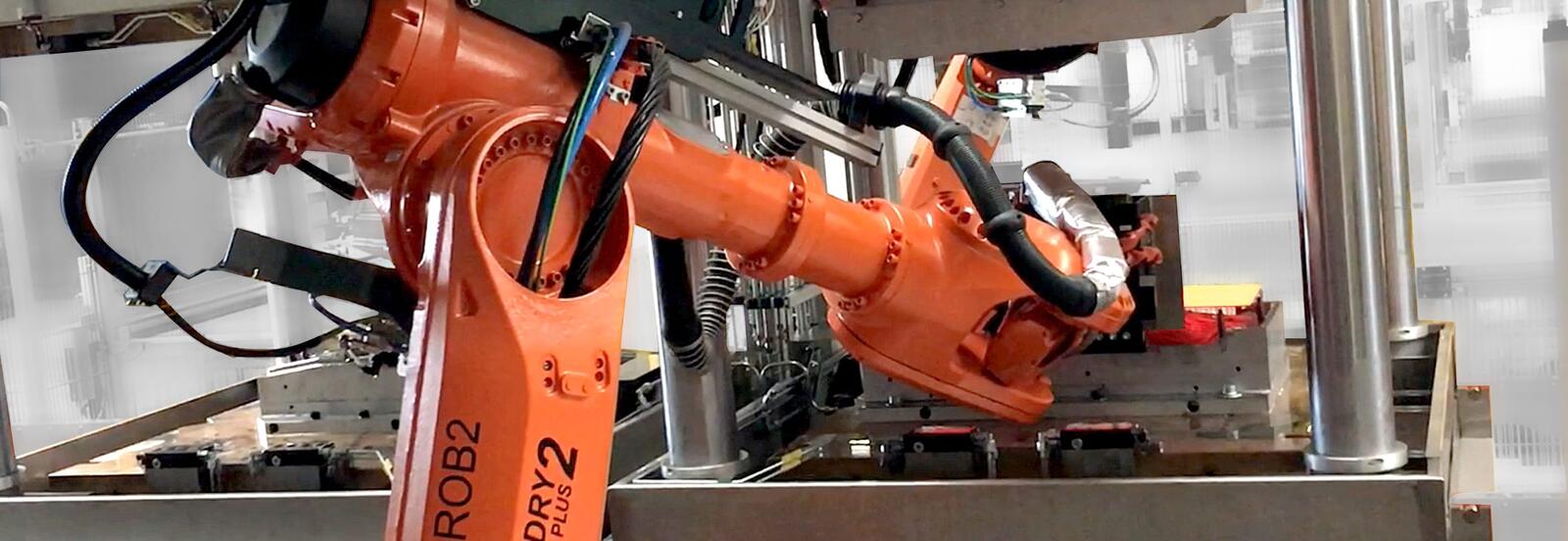

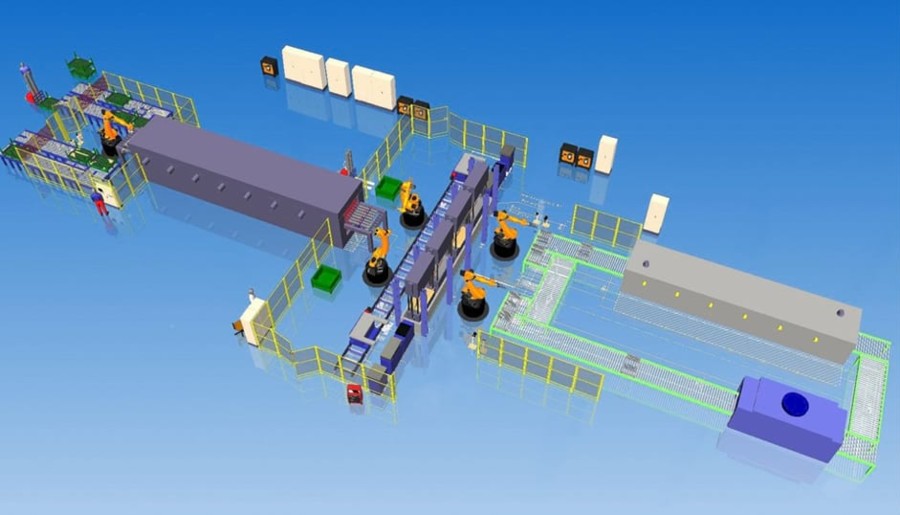

Wickert has developed an assembly line, which combines forming and hardening in one single operation.

Similar assembly lines usually consist of a high-temperature furnace and a forming press with integrated quenching. Water, polymer or hardening oil can be used for quenching.

When combining forming and quenching, a metal sheet is heated up to a temperature of about 950 °C. It is then placed into the forming press, where it is formed and quenched within the forming tool. The forming tool is modified accordingly.

This way parts, like wear parts for agricultural machines, can be produced at a lower investment and production cost, compared to conventional manufacturing. With conventional manufacturing the work piece is formed first and then in a second step it is placed in a second press to harden the material. This extra time is saved using the combined method.

Ensured hardening

Another advantage is the quick contact between material and quenching medium, ensuring quenching at the right temperature. That usually prevents the development of ferretic structures. That is a big advantage when working with thin boards of about 2 - 4 mm.