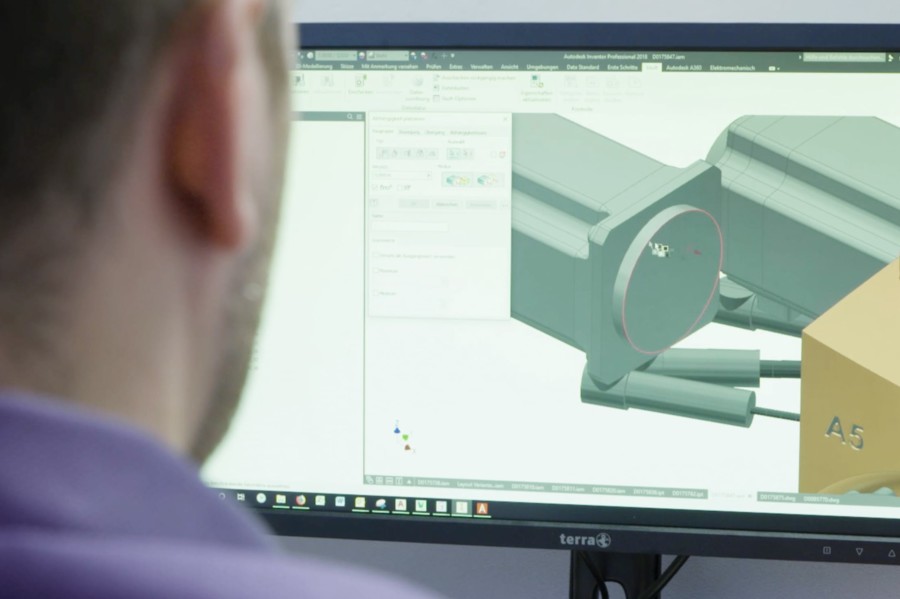

In addition to our hardening presses, we also construct hardening and forming tools for our customers.

That enables perfect adjustment of the links between tool and press.

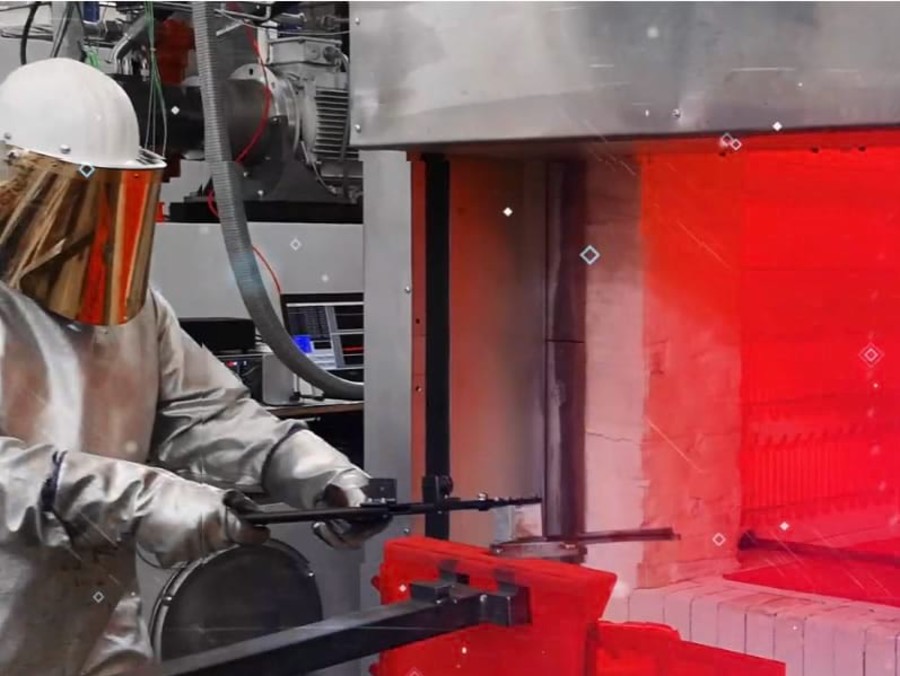

Our fluid technicians support us, when using hydraulic tools in a mechanical construction.

An optimal flow of the quenching medium is ensured.

We build tools for quenching with and without forming function.

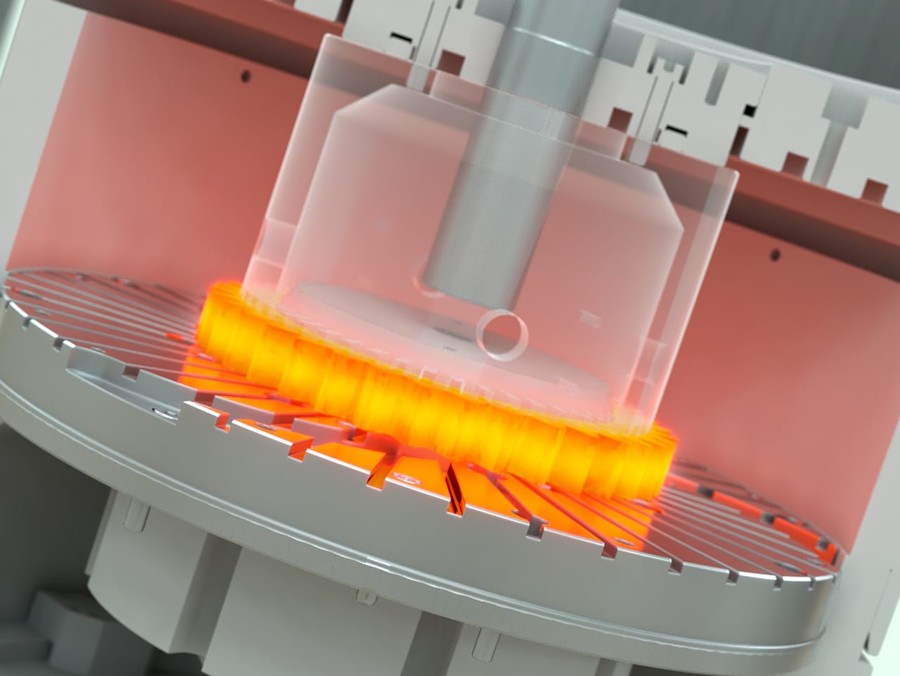

We build tools for press hardening with indirect cooling and forming function.

For the fixture hardening we build basic devices with exchange components, to ensure an economic projection of a broad spectrum of components.

Automation concepts complete our offer and create key-ready hardening systems.