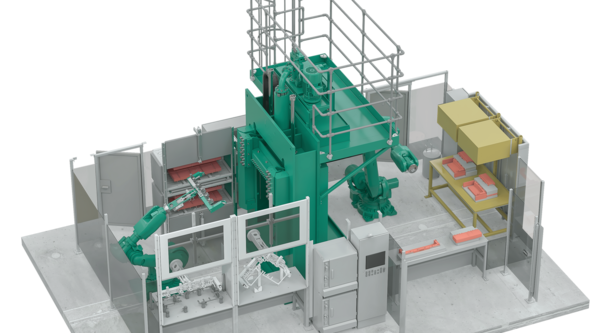

Our own process and systems development departments allows us to devise customised automation concepts and solutions for a wide variety of processes and materials. We can carry out full feasibility studies, profit calculations or in-house material and process technology tests on request.

Specific press dimensions individually selectable from 5 - 110 000 kN with platen sizes also over 10 000 mm in length and several daylights.